View More >>

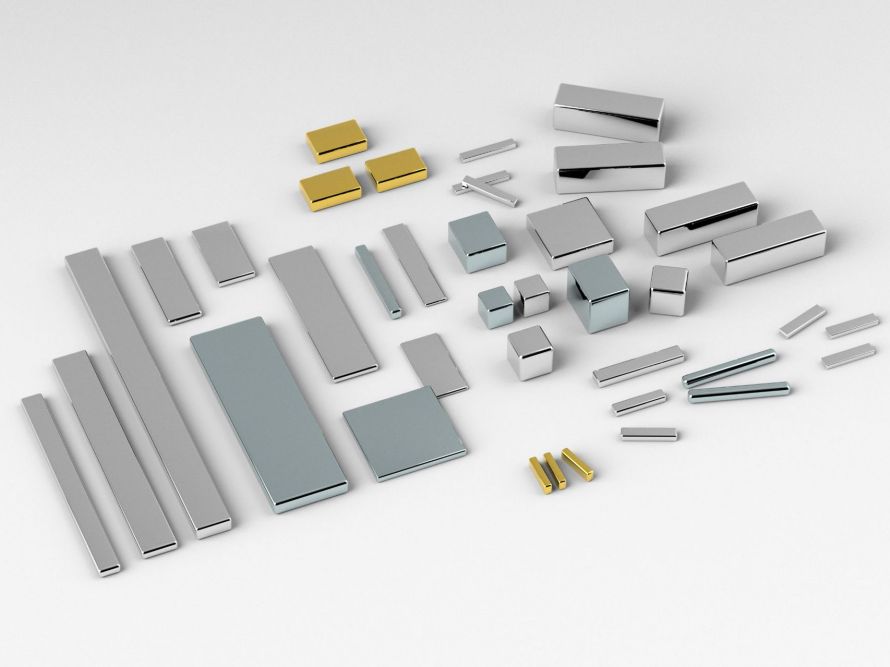

NdFeB

Neodymium iron boron: It is a tetragonal crystal formed by neodymium, iron, and boron (Nd2Fe14B). Its main raw materials include rare earth metal neodymium 29% -32.5%, metallic elements iron 63.95% -68.65%, non-metallic elements boron 1.1% -1.2%, added elements such as dysprosium 0.6% -8% niobium 0.3% -0.5% aluminum 0.3% -0.5% copper 0.05% -0.15%.

Sintered neodymium iron boron permanent magnet materials have excellent magnetic properties and are widely used in fields such as electronics, power machinery, medical equipment, toys, packaging, hardware machinery, aerospace, etc. Common ones include permanent magnet motors, speakers, magnetic separators, computer disk drives, magnetic resonance imaging equipment instruments, etc.

Process flow: batching → melting and ingot making/strip throwing → powder making → molding → sintering and tempering → magnetic testing → grinding processing → pin cutting processing → electroplating → finished product. The ingredients are the foundation, and sintering and tempering are the key.

Production tools and performance testing tools for Nd-Fe-B magnet blanks: smelting furnace, belt throwing furnace, jaw crusher, air flow mill, press forming machine, vacuum packaging machine, isostatic press, sintering furnace, heat treatment Vacuum furnace, magnetic property tester, Gauss meter.

Neodymium iron boron magnet machining tools: centerless grinding, rounding machine, double end grinding, flat grinding, slicing machine, double-sided grinding, wire cutting, bench drill, irregular grinding, etc.

Surface treatment of neodymium iron boron: Common surface treatment methods: 1. Non coating treatment of nano (Royce3010) chelating film; 3010 refers to the film layer containing 3 or more active chelating groups, with a thickness of 10 nanometers; 2. Phosphating; 3. Electroplating; 4. Electrophoresis; 5. Vacuum vapor deposition; 6. Chemical plating; 7. Organic spray molding.

The company has a complete industrial chain, providing one-stop services from raw materials, production, processing, sales to after-sales service.

Physical properties of neodymium iron boron

| Category | Parameter | Unit | Reference value | |

| Mechanical and physical properties | Density | g/cm2 | 7.40~7.70 | |

| Vickers Hardness | HV | 500~700 | ||

| Compressive Strength | MPa | 1000~1100 | ||

| Tensile Strength | MPa | 80~90 | ||

| Bending Strength | MPa | 150~400 | ||

| Thermal Conductivity | W/(m.K) | 8~10 | ||

| Young's modulus | Gpa | 150~200 | ||

| Resistivity | C//(20℃) | μΩ·m | 1.4~1.6 | |

| C丄(20℃) | μΩ·m | 1.2~1.4 | ||

| Thermal expansion coefficient | C//(20℃~100℃) | 10-6/K | 4~9 | |

| C丄(20℃~100℃) | 10-6/K | -2~0 | ||

| Maximum Service Temperature |

N | ℃ | ≤80 | |

| M | ℃ | ≤100 | ||

| H | ℃ | ≤120 | ||

| SH | ℃ | ≤150 | ||

| UH | ℃ | ≤180 | ||

| EH | ℃ | ≤200 | ||

| TH | ℃ | ≤230 | ||

|

Note 1: C//is the value measured in the direction of easy magnetization, and C Å is the value measured perpendicular to the direction of easy magnetization. Note 2: The maximum operating temperature is related to the design and size of the magnet application. |

||||

Performance parameter table of neodymium iron boron

| Breed | Character grade | Simplified code | Main magnetic properties | Squareness | |||||||

| Br | HcJ | HcB |

(BH)max |

Hk/HcJ | |||||||

| T | KG | kA/m | kOc | kA/m | kOe | kJ/㎡ | MGOe | % | |||

| Min | Min | Min | Range Value | Min | |||||||

| N | S-NdFeB-430/88 | N54 | 1.45 | 14.5 | 875 | 11 | 836 | 10.5 | 406~438 | 51~55 | 95 |

| S-NdFeB-415/96 | N52 | 1.42 | 14.2 | 960 | 12 | 836 | 10.5 | 390~422 | 49~53 | 95 | |

| S-NdFeB-400/96 | N50 | 1.39 | 13.9 | 960 | 12 | 836 | 10.5 | 374~406 | 47~51 | 95 | |

| S-NdFeB-380/96 | N48 | 1.37 | 13.7 | 960 | 12 | 836 | 10.5 | 358~390 | 45~49 | 95 | |

| S-NdFeB-360/96 | N45 | 1.33 | 13.3 | 960 | 12 | 860 | 10.8 | 342~366 | 43~46 | 95 | |

| S-NdFeB-335/96 | N42 | 1.29 | 12.9 | 960 | 12 | 860 | 10.8 | 318~342 | 40~43 | 95 | |

| S-NdFeB-320/96 | N40 | 1.26 | 12.6 | 960 | 12 | 860 | 10.8 | 302~326 | 38~41 | 95 | |

| S-NdFeB-300/96 | N38 | 1.23 | 12.3 | 960 | 12 | 860 | 10.8 | 287~310 | 36~39 | 95 | |

| S-NdFeB-280/96 | N35 | 1.18 | 11.8 | 960 | 12 | 860 | 10.8 | 263~287 | 33~36 | 95 | |

| M | S-NdFeB-415/104 | N52M | 1.42 | 14.2 | 1035 | 13 | 995 | 12.5 | 390~422 | 49~53 | 95 |

| S-NdFeB-400/111 | N50M | 1.39 | 13.9 | 1114 | 14 | 1035 | 13.0 | 374~406 | 47~51 | 95 | |

| S-NdFeB-380/111 | N48M | 1.37 | 13.7 | 1114 | 14 | 1012 | 12.7 | 358~390 | 45~49 | 95 | |

| S-NdFeB-360/111 | N45M | 1.33 | 11.8 | 1114 | 14 | 971 | 12.2 | 342~366 | 43~46 | 95 | |

| S-NdFeB-335/111 | N42M | 1.29 | 12.9 | 1114 | 14 | 938 | 11.8 | 318~342 | 40~43 | 95 | |

| S-NdFeB-320/111 | N40M | 1.26 | 12.6 | 1114 | 14 | 910 | 11.4 | 302~326 | 38~41 | 95 | |

| S-NdFeB-300/111 | N38M | 1.23 | 12.3 | 1114 | 14 | 876 | 11.0 | 287~310 | 36~39 | 95 | |

| S-NdFeB-280/111 | N35M | 1.18 | 11.8 | 1114 | 14 | 860 | 10.8 | 263~287 | 33~36 | 95 | |

| H |

S-NdFeB-400/127 | N50H | 1.39 | 13.9 | 1274 | 16 | 1035 | 13.0 | 374~406 | 47~51 | 95 |

| S-NdFeB-380/127 | N48H | 1.37 | 13.7 | 1274 | 16 | 1000 | 12.8 | 358~390 | 45~49 | 95 | |

| S-NdFeB-360/135 | N45H | 1.33 | 13.3 | 1353 | 17 | 995 | 12.5 | 342~366 | 43~46 | 95 | |

| S-NdFeB-335/135 | N42H | 1.29 | 13.7 | 1353 | 17 | 957 | 12.0 | 318~342 | 40~43 | 95 | |

| S-NdFeB-320/135 | N40H | 1.26 | 12.6 | 1353 | 17 | 930 | 11.7 | 302~326 | 38~41 | 95 | |

| S-NdFeB-300/135 | N38H | 1.23 | 12.3 | 1353 | 17 | 910 | 11.4 | 287~310 | 36~39 | 95 | |

| S-NdFeB-280/135 | N35H | 1.18 | 11.8 | 1353 | 17 | 876 | 11.0 | 263~287 | 33~36 | 95 | |

| S-NdFeB-260/135 | N33H | 1.14 | 11.4 | 1353 | 17 | 844 | 10.6 | 247~271 | 31~34 | 95 | |

| SH |

S-NdFeB-380/151 | N48SH | 1.37 | 13.7 | 1512 | 19 | 995 | 12.5 | 390~422 | 49~53 | 95 |

| S-NdFeB-360/159 | N45SH | 1.33 | 13.3 | 1592 | 20 | 1035 | 13.0 | 374~406 | 47~51 | 95 | |

| S-NdFeB-335/159 | N42SH | 1.29 | 12.9 | 1592 | 20 | 1012 | 12.7 | 358~390 | 45~49 | 95 | |

| S-NdFeB-320/159 | N40SH | 1.26 | 12.6 | 1592 | 20 | 971 | 12.2 | 342~366 | 43~46 | 95 | |

| S-NdFeB 300/159 | N38SH | 1.23 | 12.3 | 1592 | 20 | 938 | 11.8 | 318~342 | 40~43 | 95 | |

| S-NdFeB-280/159 | N35SH | 1.18 | 11.8 | 1592 | 20 | 910 | 11.4 | 302~326 | 38~41 | 95 | |

| S-NdFeB-260/159 | N33SH | 1.14 | 11.4 | 1592 | 20 | 876 | 11.0 | 287~310 | 36~39 | 95 | |

| UH |

S-NdFeB-360/191 | N45UH | 1.33 | 13.3 | 1592 | 24 | 976 | 12.2 | 342~366 | 43~46 | 95 |

| S-NdFeB-335/199 | N42UH | 1.29 | 12.9 | 1911 | 25 | 938 | 11.8 | 318~342 | 40-43 | 90 | |

| S-NdFeB-320/199 | N40UH | 1.26 | 12.6 | 1990 | 25 | 912 | 11.5 | 302~326 | 38~41 | 90 | |

| S-NdFeB-300/199 | N38UH | 1.23 | 12.3 | 1990 | 25 | 886 | 11.1 | 287~310 | 36~39 | 90 | |

| S-NdFeB-280/199 | N35UH | 1.18 | 11.8 | 1990 | 25 | 845 | 10.6 | 263~287 | 33~36 | 90 | |

| S-NdFeB-260/199 | N33UH | 1.14 | 11.4 | 1990 | 25 | 816 | 10.3 | 247~271 | 31~34 | 90 | |

| S-NdFeB-240/199 | N30UH | 1.08 | 11.4 | 1990 | 25 | 756 | 9.5 | 223~247 | 28~31 | 90 | |